Technowrap

Our world class reputation is built on our ability to deliver innovative, bespoke and cost effective engineered composite solutions to some of the largest oil and gas companies globally. Our global footprint allows us to deploy trained personnel and equipment wherever they are needed, quickly and efficiently.

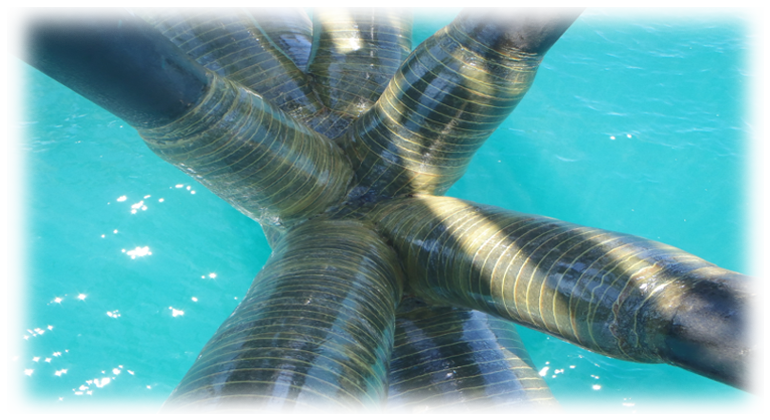

Through our Technowrap™ technology, we provide and maintain bespoke solutions to integrity management problems related to pipelines, piping systems, structures, caissons and risers and vessels in a range of conditions, with little or no downtime.

Through our Technowrap™ technology, we provide and maintain bespoke solutions to integrity management problems related to pipelines, piping systems, structures, caissons and risers and vessels in a range of conditions, with little or no downtime.

Our Technowrap™ technology has Lloyds Register “Type Approval”. This range comprises a series of design-engineered systems developed to `suit a variety of conditions. The system utilises composite technology that is internationally recognised and accredited for its outstanding performance.

Major organisations within the oil and gas industry have benefited from our Technowrap™ engineered composite solutions. Clients choose us for:

The types of corrosion, erosion defects or damage that can be repaired include:

Major organisations within the oil and gas industry have benefited from our Technowrap™ engineered composite solutions. Clients choose us for:

- Effective solutions for pipework, pipeline & structural integrity issues

- Can be applied to live systems with little or no impact on production

- Cold repair system - No hot work

- Fast, cost effective & easy to install - minimal facilities required

- Worldwide independent accreditations (Lloyds Register “Type Approval” & ABS Design & Manufacturing)

- Exceptional strength & adaptability of composites

- Long term alternative to steel replacement

The types of corrosion, erosion defects or damage that can be repaired include:

- Internal (e.g. corrosion pits)

- External (e.g. dents)

- Through-wall (e.g. leaks)

- Cracks

PRODUCT OVERVIEW

Technowrap™ composite repairs are Lloyds Register Type Approved, DNV Type Approved and ABS Design & Manufacturing Approved and are fully qualified to ISO 24817 and ASME-PCC2. All of our products go through rigorous checks and have been tested within the following range of temperatures and pressures:

All Technowrap™ Repairs come with a design life repair of up to 20 years assuming ICR perform the design of the repair and that trained Technowrap™ installers perform the application.

The resins used in Technowrap™ composite repairs are chemically resistant to a wide range of fluids present in Oil and Gas production facilities.

- Temperature range of -75 to 220°C

- Pressure range tested up to 250 bar

All Technowrap™ Repairs come with a design life repair of up to 20 years assuming ICR perform the design of the repair and that trained Technowrap™ installers perform the application.

The resins used in Technowrap™ composite repairs are chemically resistant to a wide range of fluids present in Oil and Gas production facilities.

TYPE APPROVALS – THIRD PARTY ASSURANCE

Technowrap has type approval certification from ABS, Lloyds and DNV-GL

TECHNOWRAP™ COMMON USES

Pipelines

Hydrocarbon and Utility Piping Systems

Caissons and Risers

Decks, Structures

Tanks, Cladding, Roof, Walls

Beams, Struts, Vessels